The Tudor battleship has been stabilised and is now on display in a new museum. Jon Evans explores the chemistry stopping those timbers shivering

To avoid potentially damaging shrinkage, the hull was sprayed with water for about 12 years, then with PEG for 19 years © Peter Phipp / Travelshots.com / Alamy

In many ways, the sea has not been particularly kind to the

Mary Rose, the flagship of Henry VIII’s navy when it faced an invading French fleet at the mouth of Portsmouth Harbour in July 1545. For a start, it engulfed the ship, with the loss of over 350 men.

The French claimed to have holed the Mary Rose, but there is no real evidence for this. In reality, the sinking was probably a combination of bad luck and bad seamanship. The Mary Rose was the first ship to sail out and engage three French galleys that had broken away from the fleet, during which it fired its guns. For some reason, the gun ports were then left open, allowing seawater to rush in as the Mary Rose manoeuvred, sinking it.

The Mary Rose came to rest on the seabed, around 14m down, at which point the sea really went to work. Through a combination of the abrasive action of silt flowing past and feeding by organisms such as shipworms and marine bacteria, the exposed wooden hull of the ship was quickly eroded away on the port side.

In one crucial way, however, the sea did the Mary Rose a huge favour, by gradually burying it in sediment. This covering of sediment protected the rest of the ship, together with many of the objects inside it, from further erosion and damage. ‘Basically it’s the sediments that built up over many, many centuries that helped preserve it,’ explains Mark Jones, research director at the Mary Rose Trust, the charity set up to conserve and preserve the ship.

As well as physically protecting the ship from abrasion, the sediment also created an anaerobic environment. This lack of oxygen prevented aerobic organisms from feeding on the wooden hull, and also stopped any damaging chemical reactions involving oxygen, such as metal corrosion, from taking place.

The ship’s hull was discovered in 1971 and raised from the sea in 1982 © Louie Psihoyos / Corbis

And so there the Mary Rose lay for over 400 years, before being discovered in 1971, when the first of what would eventually amount to 19,000 artefacts were brought up. Then, in 1982, what remained of the hull was raised from the seabed on live TV and carefully moved to its new home on Portsmouth dockyard.

De-salting the sea dog

If the raising of the Mary Rose was an impressive feat of engineering, it was nothing compared to the challenge of replicating the preservative effects of a simple layer of sediment. As soon as it was lifted free of the protective sediment, the Mary Rose and its artefacts began to be attacked by bacteria and fungi and to react with oxygen. Meeting this preservation challenge has kept Jones and his colleagues busy for more than 30 years, and although they have managed to overcome every problem so far thrown at them, new ones continue to appear.

Over that time, drying has remained the main aim of the preservation work. When wet, the artefacts and hull are inherently unstable and prone to deterioration, whereas they are much more stable and robust when dry.

For artefacts made of metal, stone, glass, ceramics and some fabrics, this drying process is fairly simple, merely requiring gentle heating to drive off the moisture. However, some of the more fragile artefacts made from fabrics such as leather need to be treated with waxy substances like glycerol to prevent them breaking apart as they dry. On top of this, several other treatment steps are often required to stop any further deterioration.

© Steve Vidler / Alamy

So, for example, preventing corrosion in artefacts made from metals such as iron, bronze and copper, including guns, powder scoops, nails and bolts, requires removing chloride salts. The most effective technique for doing this, especially for iron artefacts, is hydrogen reduction, which involves heating the metal artefacts to a temperature of 850°C in a hydrogen atmosphere. Although effective, this technique is highly controversial because it changes the metallurgical structure of the artefact, whereas ideally the artefact should be preserved in its original condition.

‘This is the only method that has successfully removed total chlorides from iron found in the marine environment, but we’ve stopped using it,’ says Jones. Instead, they’ve switched to other techniques, such as alkaline sulfide methods, although these tend to be much slower, especially for large objects.

Salts also need to be removed from stone, glass and ceramic artefacts, but for a different reason. ‘As these artefacts dry, salts crystallise out again and force these very pliable sections of glass apart, which just destroys the outer surface,’ explains Jones. In addition, artefacts made from natural materials need to be sterilised using chemicals or cold temperatures to kill off any bacteria or fungi that may be feeding on them.

Shower me timbers

But it’s the wooden objects and structures that present the biggest drying challenge. Before the Mary Rose became covered in its protective layer of sediment, marine bacteria and fungi had time to attack all the wooden objects, including the hull. They ate away much of the glucose-rich cellulose and hemicellulose in the cells making up these objects, leaving behind the harder-to-digest lignin.

The end result was that the cells were hollowed out. Only the lignin in the outer cell wall remained, forming a network outlining where the cells used to be, while seawater quickly entered and filled up the gaps in the hollowed-out cells. ‘What replaces the cell wall layers then is water, so that supports the shape of the cell,’ says Jones.

Smaller wooden objects could be soaked and dried easily © Rik Hamilton / Alamy

Fortunately, this only happened in the surface layers of the wooden objects, because the microbes didn’t have enough time to work their way any deeper before the covering of sediment created an anaerobic environment. ‘The first 10mm is very decayed, very soft, basically lignin, really. And that structure is just supported by water,’ reveals Jones. ‘Beneath that you’re then entering into very, very sound wood; the cell walls are saturated with water but are well preserved.’ If all this water is removed by drying, the wooden objects would shrink dramatically, by up to 50%, causing them to warp and crack.

So when the hull and other wooden objects were first raised, they were simply kept wet, while Jones and his colleagues worked out a way to dry them without causing any shrinkage. Smaller wooden objects were simply immersed in water-filled tanks and containers, while the hull itself was constantly sprayed with filtered, sterilised water, which continued until 1994.

The scheme they eventually came up with was inspired by the approach used on the Vasa, a Swedish warship that sank in Stockholm harbour in 1628 and was raised in 1961. This involves replacing the water in the wooden objects with the polymer polyethylene glycol (PEG), which prevents the objects from shrinking as they dry.

Wooden artefacts such as plates, arrows and gun-carriage wheels were immersed in a tank containing liquid solutions of PEG. The artefacts were immersed for up to six months, giving sufficient time for the PEG to penetrate deep into the wood and displace the water in the cell walls, where it bound with what remains of the cellulose via hydrogen bonds.

Next, the artefacts were freeze-dried to drive off the majority of the remaining water. This involves placing the artefacts in a sealed chamber, where they are first frozen to temperatures of around –35°C and then dried by reducing the pressure and gradually raising the temperature. The advantage of this process is that any ice formed during the freezing process sublimes directly into vapour without going through a liquid stage, reducing drying stresses and preventing damage to the wooden objects. It’s also much faster than air drying, taking two to three weeks rather than up to a year.

Treating the wooden objects with PEG and then freeze-drying them has been going on for almost 20 years now, and has been a massive undertaking. The Mary Rose Trust owns several freeze-drying chambers of different sizes, with the largest able to dry entire gun-carriage wheels and wooden beams. ‘We have probably the largest number of vacuum freeze driers for archaeological material in the UK,’ says Jones, who was awarded an MBE in the 2014 New Year honours for his work on the Mary Rose.

One hull of a challenge

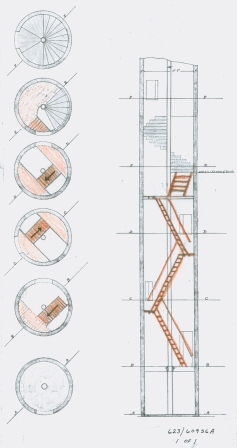

The hull of the Mary Rose, which is 32m long and weighs around 280 tonnes, presented an even greater challenge, as it is far too big to be immersed in a tank or placed in a vacuum freeze dryer. So in 1994, Jones and his team stopped spraying the hull with water and started spraying it with PEG. Initially, they used PEG with a molecular weight of 200 grams per mole, which is liquid at room temperatures and so could diffuse deep into the wood to displace the majority of the water in the sound cells. But this liquid PEG wouldn’t provide sufficient support for the completely hollowed-out cells near the surface.

So in 2006, after ensuring that the PEG 200 had diffused throughout the hull, they started spraying a solution of PEG with a molecular weight of 2000 grams per mole. Unlike its smaller cousin, PEG 2000 solidifies when dry, providing the physical support necessary to retain the structure of the hollowed-out cells.

The new £35 million museum in Portsmouth’s dockyard had to be built around the ship © Mary Rose trust

The sprayers were finally switched off at the end of April 2013, when the drying process began. This involved installing a network of ducts to transport conditioned air with a relative humidity of 55% and maintained at a temperature of 18–20°C around the hull, with the aim of steadily drawing out the moisture.

The sprayers were switched off just a month before a new £35 million museum housing the Mary Rose was opened to the public. Because the Mary Rose could not be moved, this new museum was built around the ship, with visitors now able to view the ship through windows as it dries.

As they walk past the ship on one side, the other side presents a mirror-image replica of the hull, with artefacts such as guns and the surgeon’s chest displayed in the same position as they would have been found on the actual ship. Other dried artefacts, such as longbows, clothing, glasses, coins and even the skeletons of an archer, the ship’s dog and one of the rats that the ship’s dog would have caught, are displayed in climate-controlled cases in several rooms throughout the museum.

By the end of 2015, the ship should have dried sufficiently for the network of ducts to be dismantled and the wall separating the visitors from the ship to be removed, while still maintaining the same constant temperature and relative humidity around the ship. The hull will also be cleaned, because some of the PEG 2000 has formed white deposits on it. Then, the Mary Rose will be in the most pristine state since it first sailed the seas over 500 years ago.

An ongoing concern

That doesn’t mean, however, that all the preservation work can stop, because new and unexpected challenges are arising all the time. For example, a few years ago Jones and his team discovered that sulfuric acid was forming in the hull, raising concerns that this acid could gradually degrade and break down the wooden timbers. The problem was first spotted in the Vasa, but subsequent research showed that it was also happening in the Mary Rose.

Rather unexpectedly, it turns out that the hull of the Mary Rose contains quite a lot of sulfur, around two tonnes, which is an unfortunate consequence of the anaerobic environment provided by the sediment. Although this oxygen-free environment protected the Mary Rose from aerobic organisms, it allowed anaerobic marine bacteria to thrive.

Many of these anaerobic bacteria reduce sulfates in seawater as part of their respiration process, producing hydrogen sulfide as a waste product. Over the course of more than 400 years underwater, huge amounts of this hydrogen sulfide diffused into the hull of the Mary Rose. When the hull was then raised from the seabed, the hydrogen sulfide could react with oxygen in the atmosphere to form sulfuric acid and sulfate salts.

The recovered artefacts, including metal cannons and cannonballs, had to be dried and stabilised to prevent corrosion © Steve Vidler / Alamy

What made the situation even worse is that this process is catalysed by iron, and the Mary Rose contains lots of iron in the form of guns, nails and bolts. Iron readily reacts with hydrogen sulfide to form iron sulfide, which then reacts with oxygen to form sulfuric acid.

Fortunately, this sulfuric acid is proving reasonably easy to deal with. ‘We did neutralise the acid during the PEG treatment and we removed a lot of the iron using some chelating agents,’ says Jones. Nevertheless, together with researchers at the University of Kent, Jones is also looking at a method for removing the threat of sulfuric acid altogether. This would involve spraying the hull with strontium carbonate nanoparticles, which react with the sulfur in the hull to form stable strontium sulfates that don’t react with oxygen to produce sulfuric acid. Initial studies have shown that these nanoparticles can impregnate wood and will react with the sulfur to form unreactive species.

There is, however, a potentially more insidious problem, because oxalic acid may also be forming in the hull of the Mary Rose. Oxalic acid can be produced by fungal activity, and a few active microbes will still be inside the hull, but it can also be produced by the breakdown of PEG. Again, this problem was first observed in the Vasa, but Jones and his colleagues are now looking to see whether it’s happening in the Mary Rose.

‘We are looking into this at the moment to see if we’re finding any PEG breakdown products,’ Jones says. If they do find such products, then this raises troubling questions about the long-term stability of PEG. ‘It all depends on what else is inside that timber that could interfere with the PEG,’ he adds.

The Mary Rose has been through a lot over the past 500 years and has certainly earned a comfortable retirement. As with any elderly pensioner, though, it’ll just need continual check-ups.

Jon Evans is a science writer based in Bosham, UK

From April 12-30, members of the public are invited to join NOAA Ship Okeanos Explorer as it explores deep-sea habitats in the Gulf of Mexico. Virtual ocean explorers will have the chance to see canyons, deep-sea coral communities, and shipwrecks dating to the early 1800s via live video transmitted from the deep seafloor.

From April 12-30, members of the public are invited to join NOAA Ship Okeanos Explorer as it explores deep-sea habitats in the Gulf of Mexico. Virtual ocean explorers will have the chance to see canyons, deep-sea coral communities, and shipwrecks dating to the early 1800s via live video transmitted from the deep seafloor. “America's Gulf is our backyard, yet there is a great deal we still need to learn about its sea floor, sea life and maritime heritage," he added.

“America's Gulf is our backyard, yet there is a great deal we still need to learn about its sea floor, sea life and maritime heritage," he added. Technicians aboard the ship will launch Remotely-Operated Vehicles (ROVs), allowing scientists on shore to explore features such as salt domes, gas seeps, and canyons, while also investigating shipwrecks and marine life, including deep-sea coral habitats. NOAA’s ROV Deep Discoverer, accompanied by the ROV camera-sled Seirios, are equipped with high-definition video cameras and advanced lighting systems to obtain and send live video. The ROVs may operate as deep as 3,000 meters.

Technicians aboard the ship will launch Remotely-Operated Vehicles (ROVs), allowing scientists on shore to explore features such as salt domes, gas seeps, and canyons, while also investigating shipwrecks and marine life, including deep-sea coral habitats. NOAA’s ROV Deep Discoverer, accompanied by the ROV camera-sled Seirios, are equipped with high-definition video cameras and advanced lighting systems to obtain and send live video. The ROVs may operate as deep as 3,000 meters.